PNP

PNP

The first unit of the Technology Seminar class asked us to collaborate and create a nameplate for the admissions team.

Though I don’t have everything recorded, I still want to share some of my approaches and progress.

Background

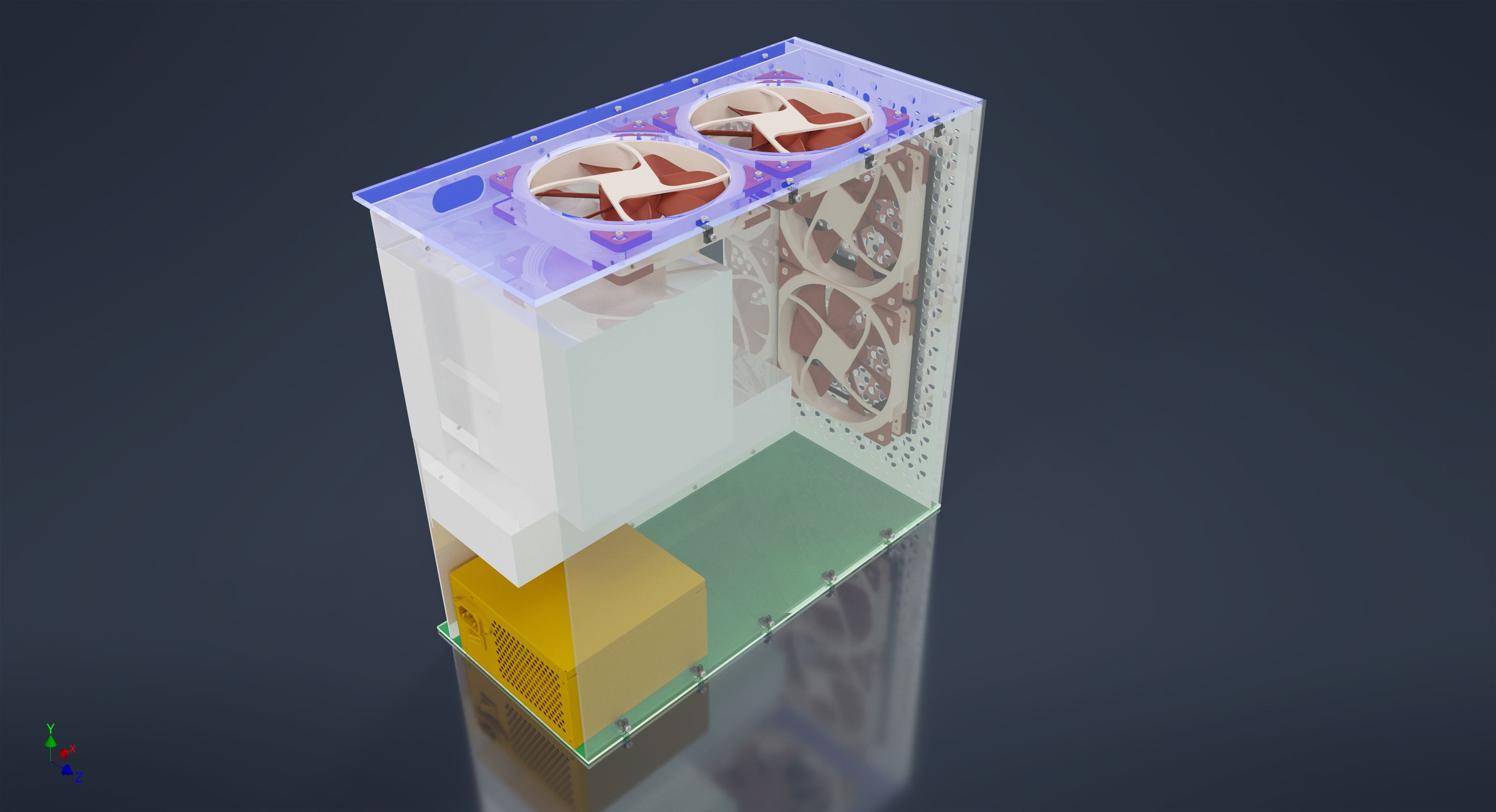

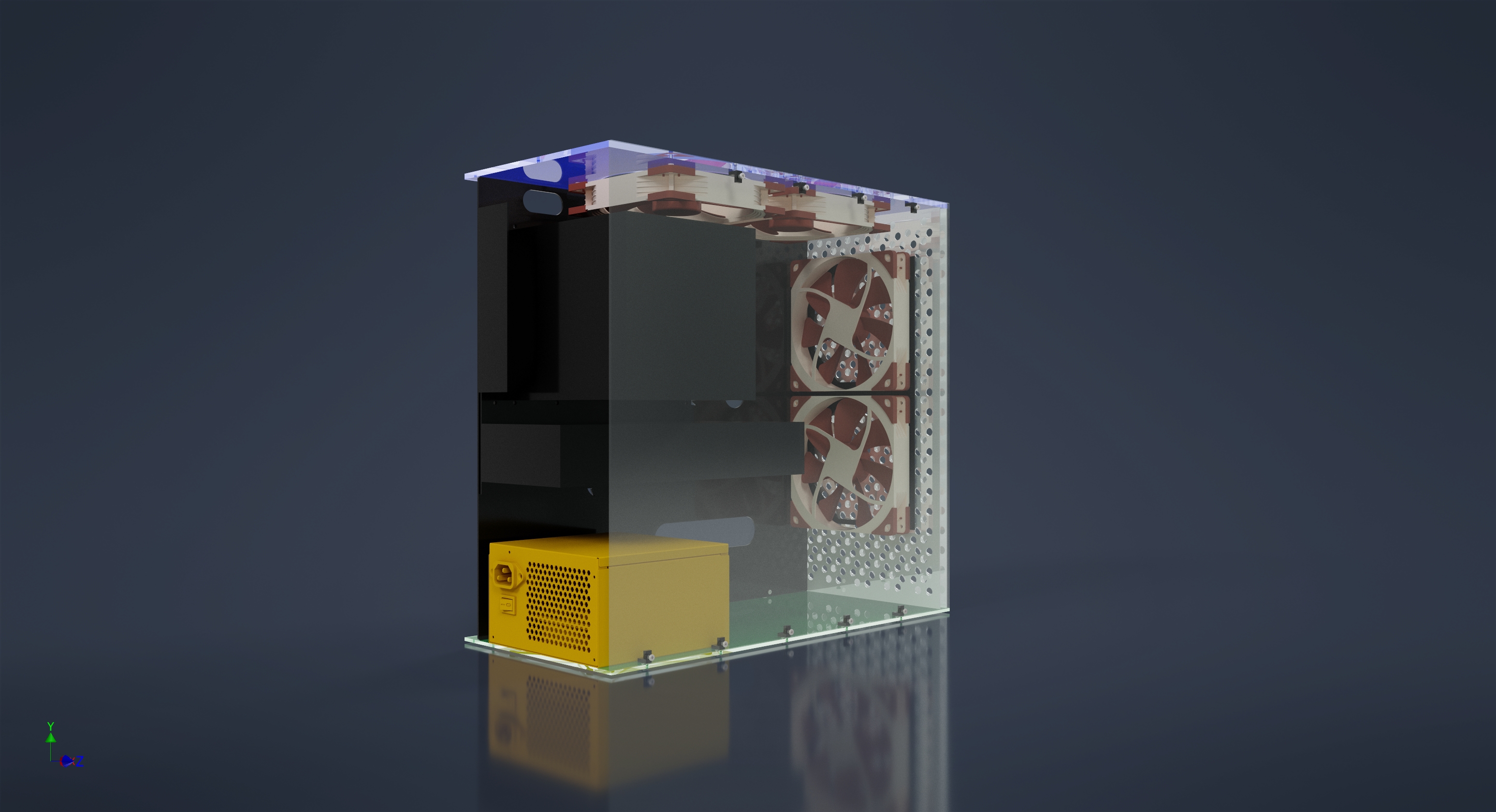

Before this project, I already had some experience in CAD — I made my own PC case.

It was my first big CAD project and took about a month… and it was painful.

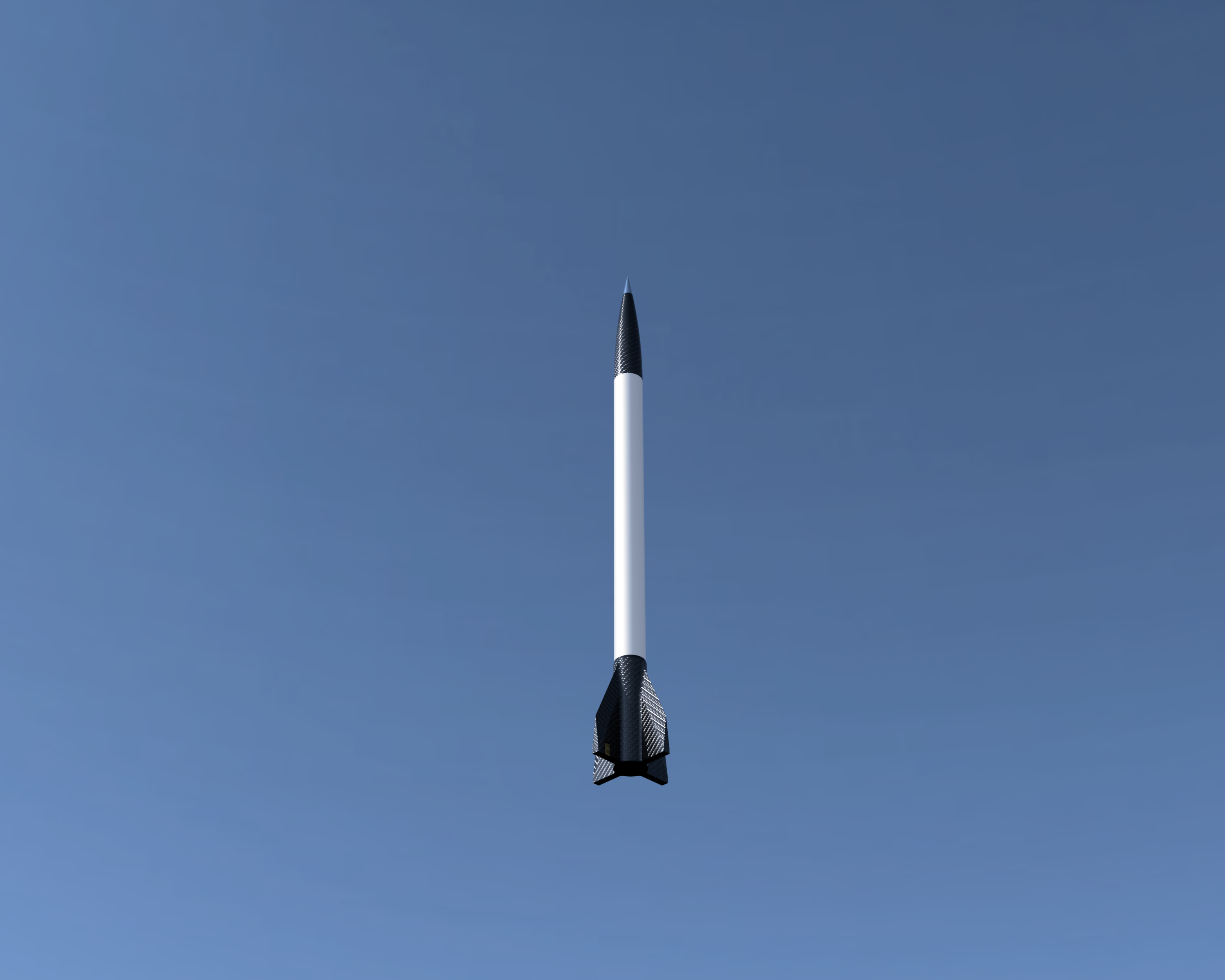

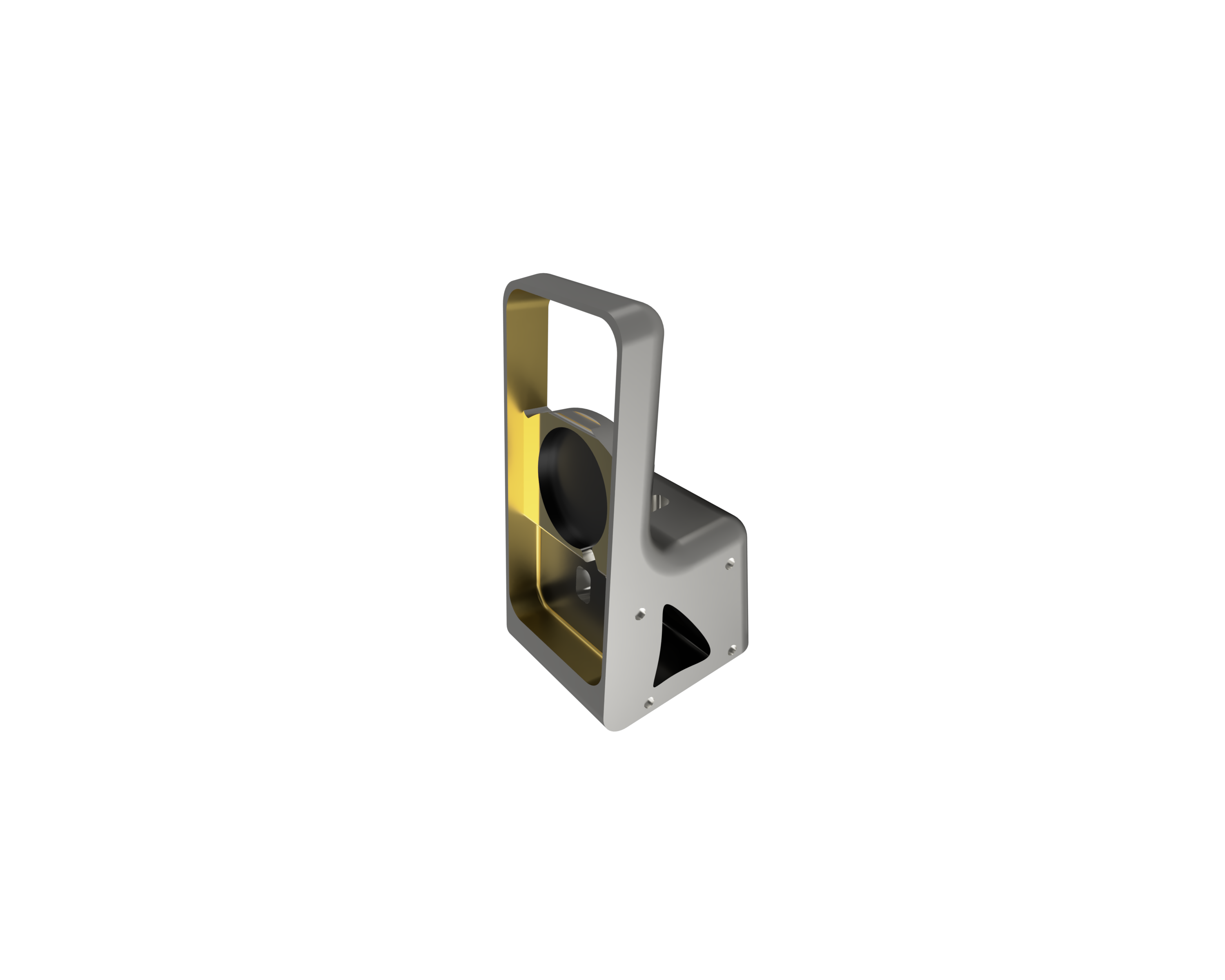

Here’s a little gallery walk:

Looks cool, right? But it only looks cool.

I didn’t leave enough margin for testing and wasn’t careful with the details — I accidentally rotated the motherboard holes by 90°. It was a disaster.

I ran out of both budget and time because school was starting.

Those mistakes became recurring themes throughout the school year.

On Time, On Scope, On Budget

Project: Nameplate

My initial approach was simple — just make a nameplate.

And I went as creative as possible.

Since I didn’t have a defined plan, I made several.

Gallery Walk

Thoughts

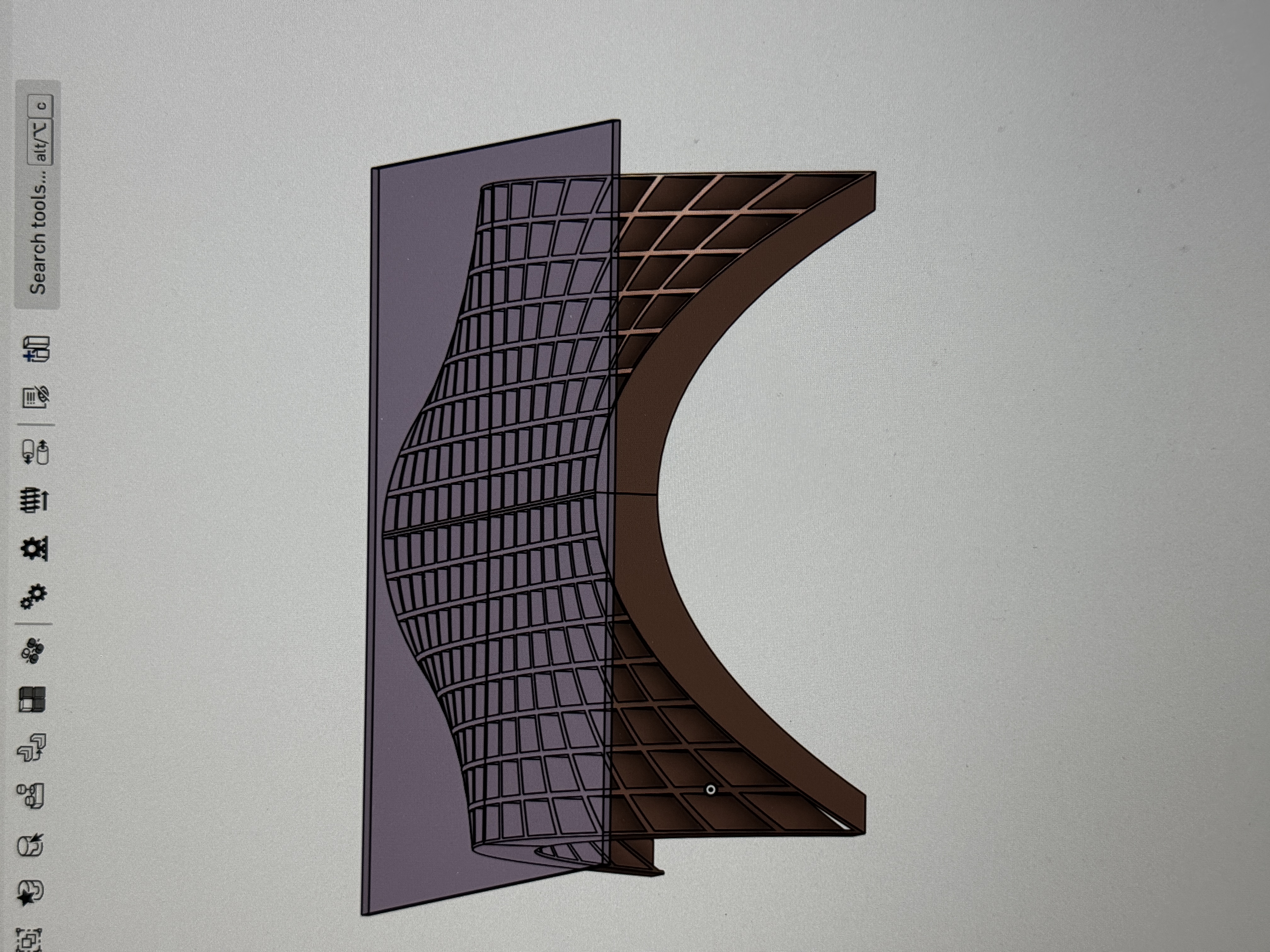

During this phase, I explored every Onshape tutorial I could find.

I learned a ton, but it was also draining.

In my designs, I experimented with many tools:

- Lighten feature-script (inspired by robotics)

- Loft (inspired by topology)

- Semicircle circular pattern on a circular pattern — “Roman temple” style

But did the results look nice? Nope.

I had to stay on scope.

That’s when I started searching for a unique approach.

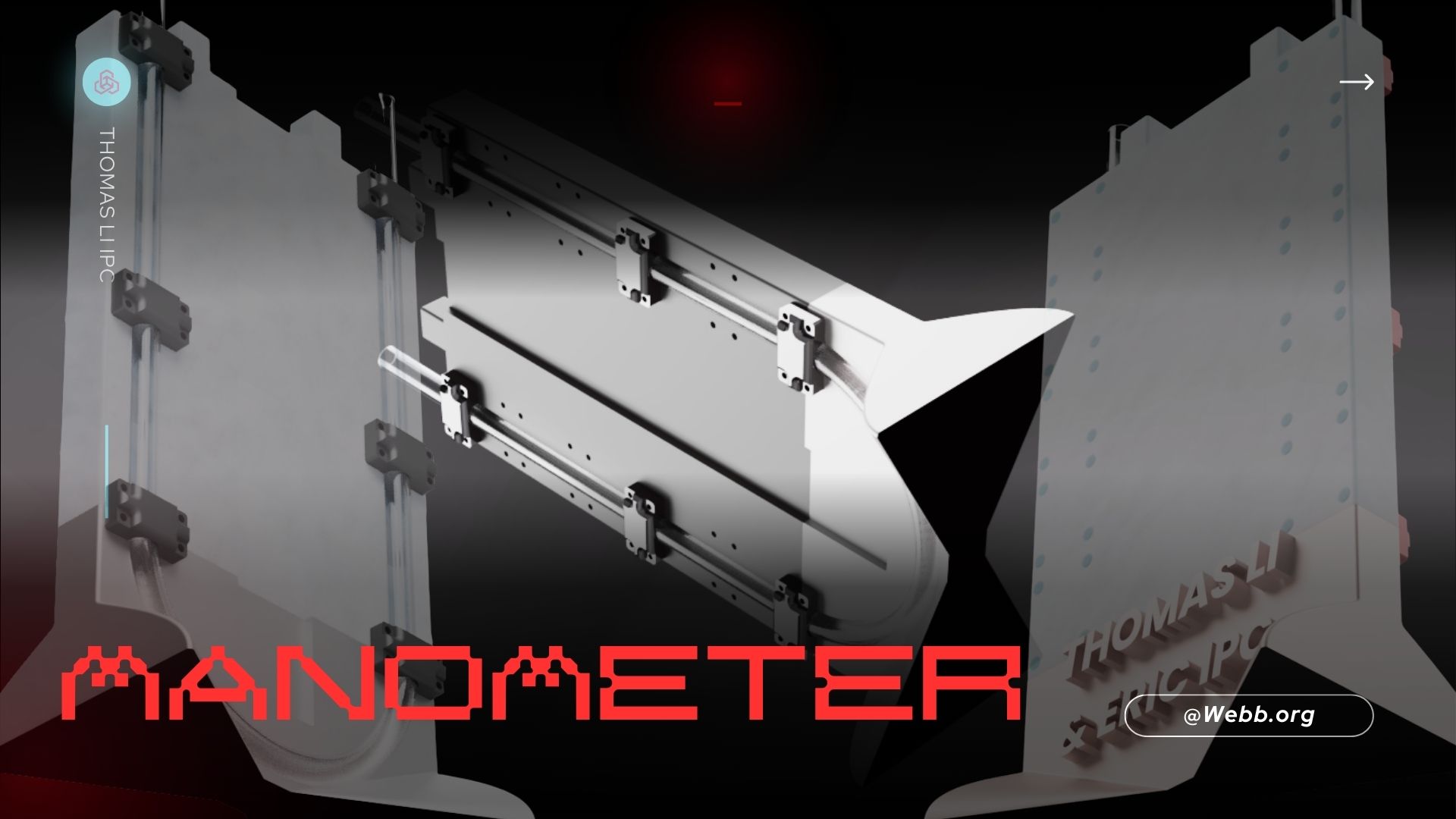

Dual Nameplate

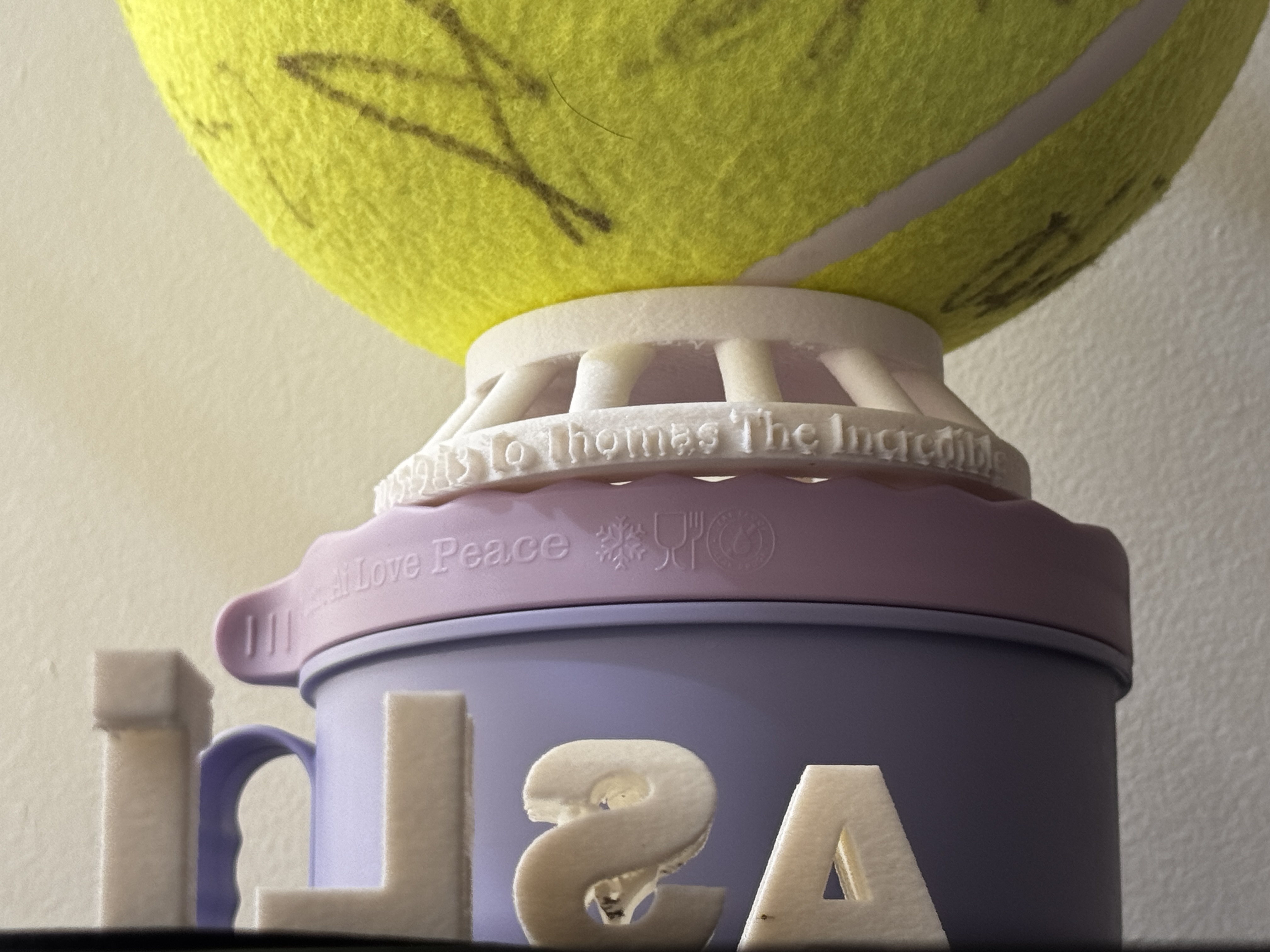

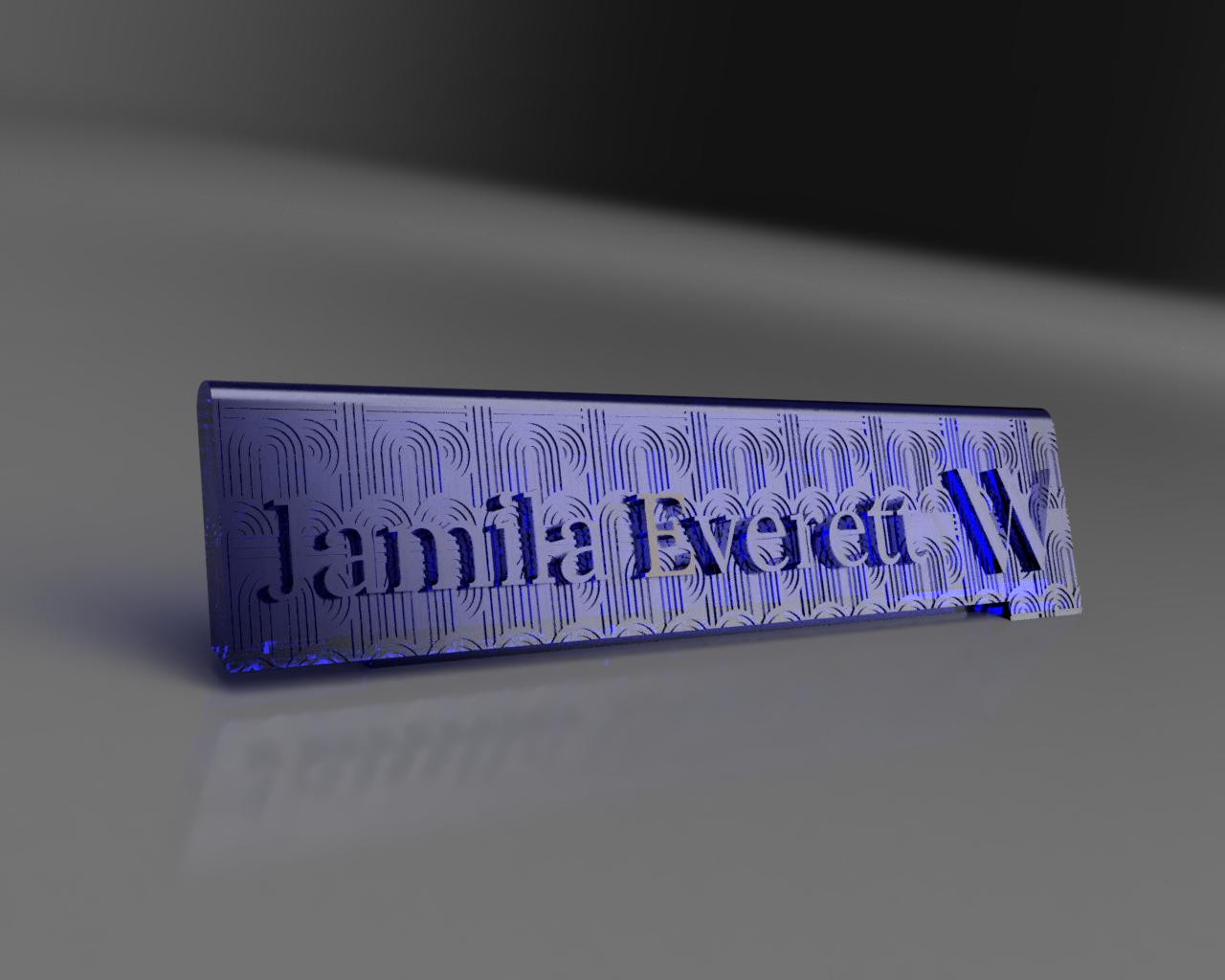

Finally, I settled on the “Dual Nameplate” design.

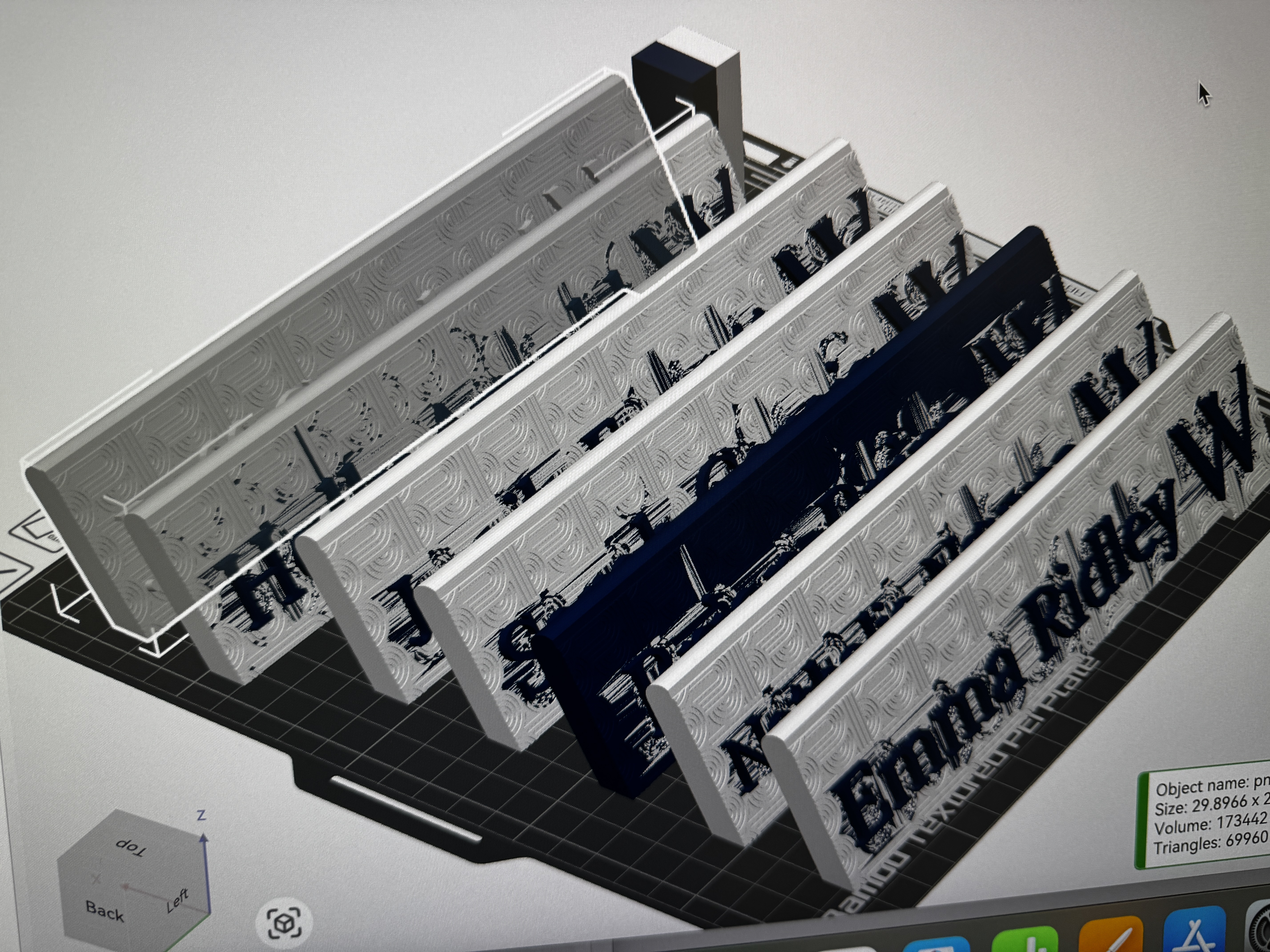

Here’s another gallery walk:

I even made a version for my school — but I didn’t check the support structure, which made it fragile and hard to remove.

Dual Webb

Back to Topic

Finally, I still had to complete the team project.

We asked our clients (the admissions team) for their requirements:

- Font: Lora

- Dimensions: 2 × 8 × 1 in

- Theme: School-oriented, professional

- Must be presentable

My teammate and I focused on the achievable goals and trimmed away excessive ideas.

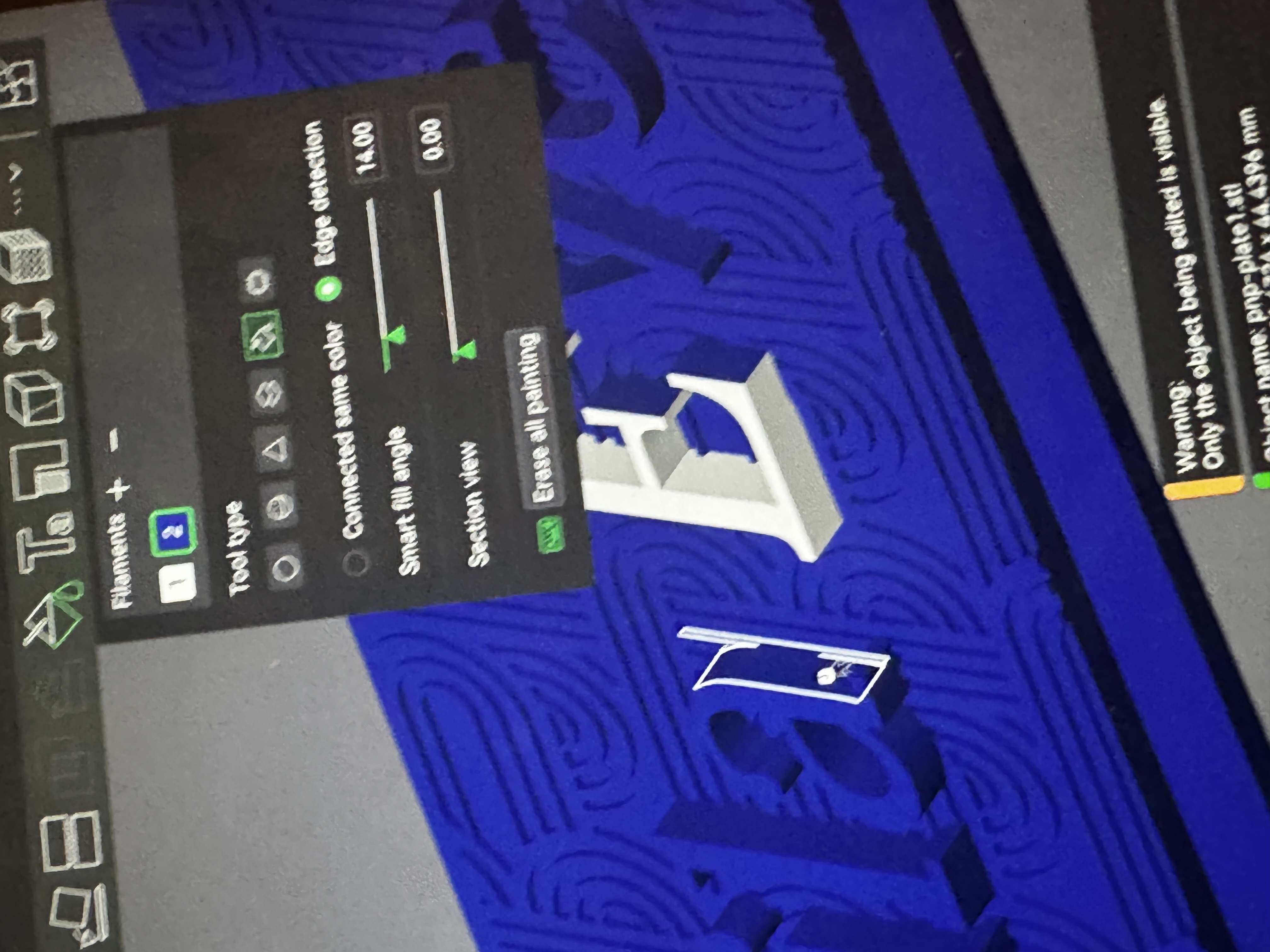

We created a school-themed pattern in Fusion and mirrored it for balance.

Then, we added a sliding mechanism so the base could be printed separately — reducing failure risk.

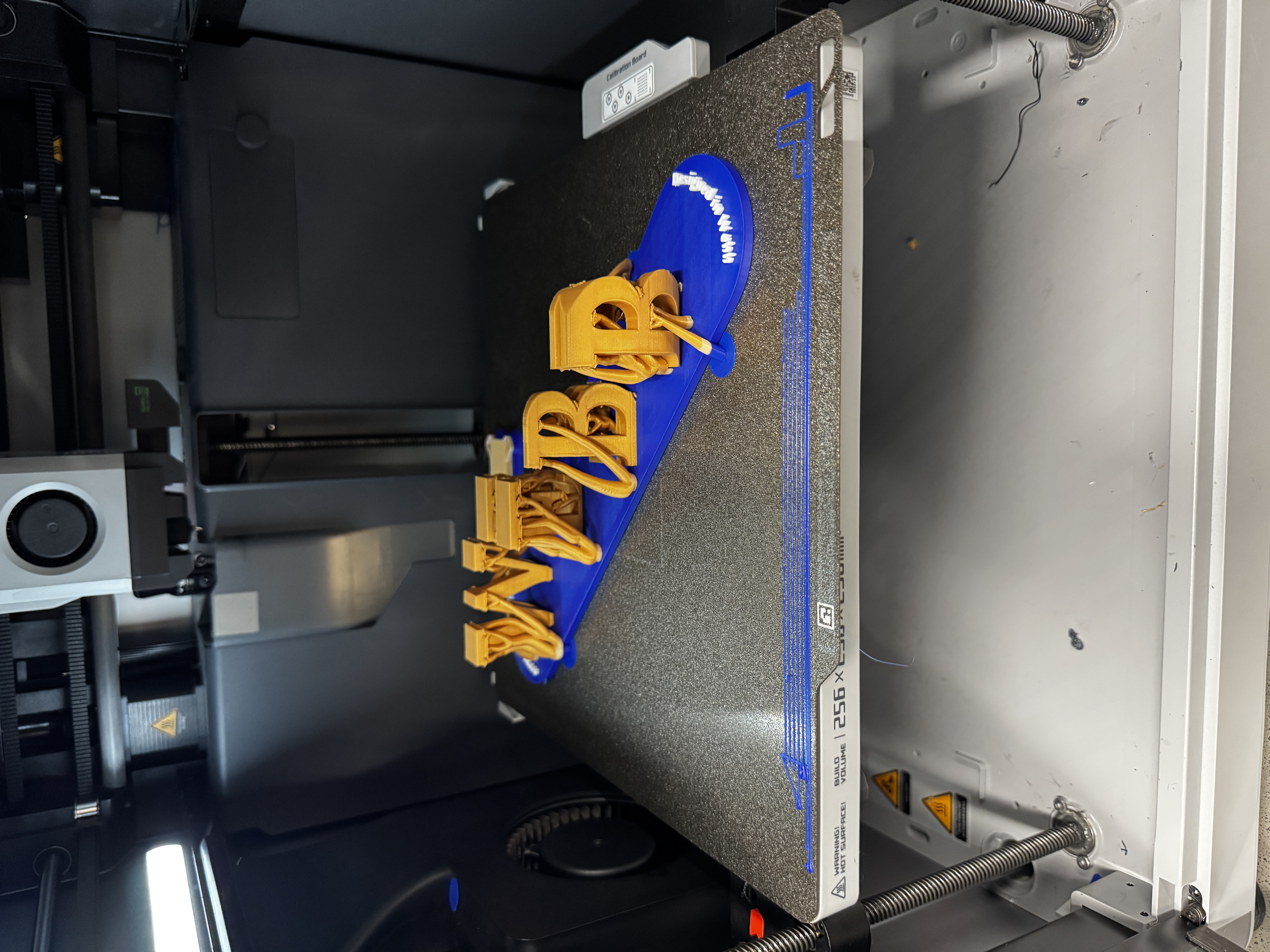

After several rounds of printing and adjustments, we finally got there.

Finale

This is the final print time-lapse — 24 hours!

Teamwork makes the dream work.

Improvements for the Future

- Better locking system

- Cleaner CAD structure

- Tuned Bambu Lab settings

- Clearer time management

- Stronger teamwork

Extra Photos